Production process

VTR-Y LINE

YUYAO production line, equipped with voice control and Fibersort technologies

00 OBTAINING RAW MATERIAL

Play Video

01 UNLOADING

Play Video

02A FIRST SORTING

Play Video

02B FIRST SORTING

Play Video

03 VOICE CONTROL

Play Video

04 FIBRESORT

Play Video

05A PACKAGING

Play Video

05B PACKAGING

Play Video

VTR-O LINE

1 UNLOADING

Our work begins by unloading the raw material delivered to the plant.

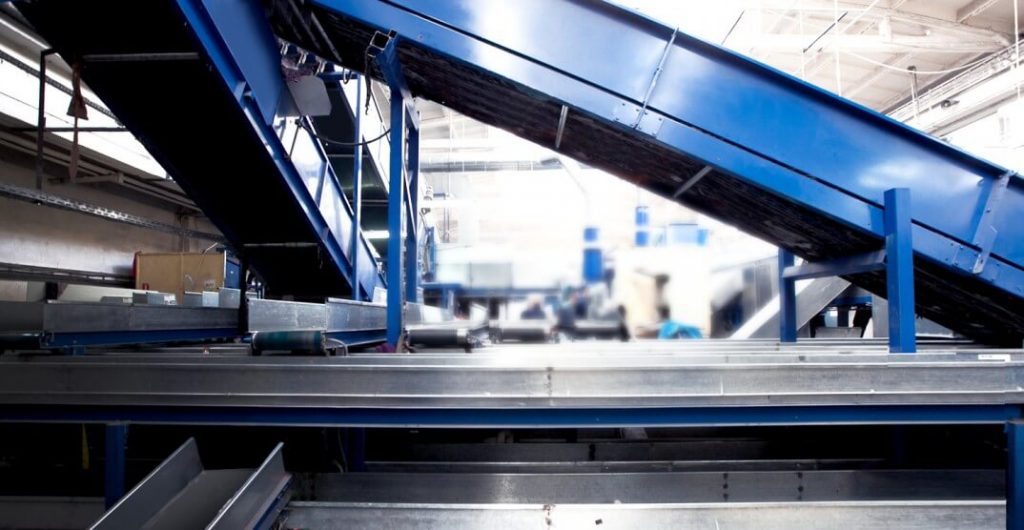

2 SORTING DEPARTMENT I

Then the raw material is subjected to preliminary segregation and is transported to the belt conveyors, which transport it to the Sorting Department I.

3 SORTING DEPARTMENT II

After preliminary sorting, the raw material is transferred to Sorting Department II, to which only clothing is delivered.

4 SORTING BY TYPE

Sorting Department II employees group clothes into different types, separating them into individual backfill chambers.

5 Sorting Department III

Grouped clothes are transferred to Sorting Department III, where specific groups of textiles are divided into grades, adjusted to the quality requirements of the customers. Clothing is classified individually and if it does not meet the requirements, it turned into industrial cleaning cloth, alternative fuel or composite boards.

6 PACKAGING DEPARTMENT

After the completion of the third sorting sequence, the products are sent to the Packaging Department. The goods are packed in bags or pressed into bales.

7 WEIGHING AND MARKING

Packaged textiles are precisely weighed and barcoded.

8 WAREHOUSES

The finished product, now in special containers, is transported to the warehouse or is immediately loaded. The warehouses receive 1500 tons of finished products from the Production Department every week.

9 OTHER TEXTILES

Textiles intended for industrial cleaning will be sent to the Cutting Facility. Textiles that cannot be used as a cleaner will be processed further. They are used in production of alternative fuel, PE granulate or composite boards.